Color coated aluminum plate

Color coated aluminum sheet, which can be made into pressed aluminum sheet, corrugated aluminum sheet, corrugated aluminum sheet, is a pressed aluminum sheet that is rolled and cold bent into various wave shapes.

Description

Color coated aluminum plate

Color coated aluminum sheet, which can be made into pressed aluminum sheet, corrugated aluminum sheet, corrugated aluminum sheet, is a pressed aluminum sheet that is rolled and cold bent into various wave shapes. Corrugated aluminum sheet (corrugated aluminum sheet) has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fire prevention, rainproof, long service life, maintenance-free, etc., and is now widely promoted and applied.

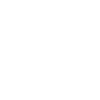

Color production process

Color aluminum plate adopts aluminum alloy material, through hot rolling and cold rolling repeatedly processed, made of uniform thickness of the color plate volume, color plate volume after double-sided surface coating process, become a color aluminum flat plate, and again through the stereotypes of the pressure plate machine processing, pressed into a variety of specifications, models of the color aluminum corrugated aluminum color aluminum plate

Main features: superior environmental protection and energy saving effect, beautiful appearance and color variety, superior plasticity, outstanding durability and practicality.

Applications

Color aluminum panels are widely used in exhibition centers, stadiums, commercial centers and other large-scale public facilities, factories, airport terminals, high-speed rail stations, commercial shopping centers and other industrial and civil buildings.

Color coated sheet production line #1

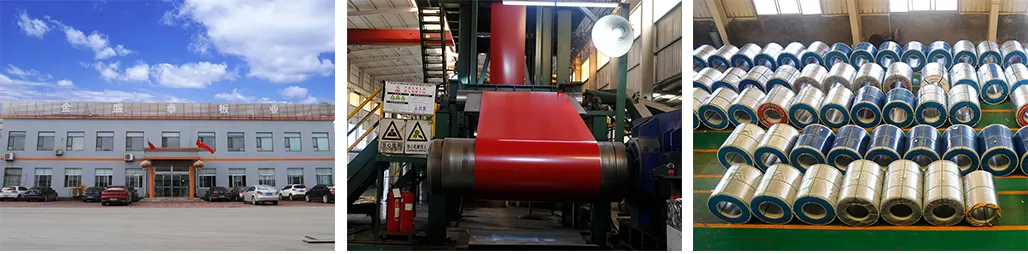

The color-coated sheet production line #1 of Binzhou Jinshengtai Industry Co., Ltd., was initially built in 2009 and began operations in February 2010. The line was designed to operate at a speed of 120 meters per minute with an annual production capacity of 120,000 tons, producing sheets with thicknesses ranging from 0.12 to 0.8 millimeters and widths from 700 to 1250 millimeters. The yield strength of the products varies between 210 and 550 MPa. In 2021, over an 8-month period, enhancements and updates have been made to the original production line's equipment and techniques, enabling customization of paint finishes and processes based on client needs. Available paint finishes encompass standard polyester, specialized polyester for appliances, dedicated polyester for chalkboards, and several other major categories. The color-coating line adopts a series of advanced technologies and equipment, including roller passivation, FATA single-rail coaters, rapid color change systems, clean air heating systems, and cold laminating processes, capable of delivering a wide array of color-coated products in various colors and series. These include standard building panels, high-strength, stamping-grade premium building panels, chalkboard panels, appliance panels and color-coated aluminum panels.

Category:

Color coated aluminum plate

Keywords:

Color coated aluminum plate