Color coated sheet

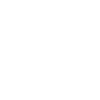

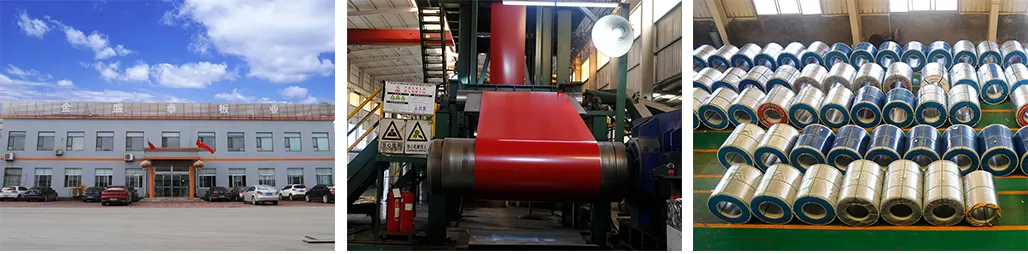

The color-coated sheet production line #1 of Binzhou Jinshengtai Industry Co., Ltd., was initially built in 2009 and began operations in February 2010. The line was designed to operate at a speed of 120 meters per minute with an annual production capacity of 120,000 tons, producing sheets with thicknesses ranging from 0.12 to 0.8 millimeters and widths from 700 to 1250 millimeters.

Description

Color coated steel sheet

Loading→Unwinding→Shearing→Sewing & Flattening→Tensioning & Conveying→Rinsing→Degreasing→Roller Brushing→Cleaning→Passivation→Drying→Primer Roller Coating→Primer Curing→Exhaust Gas Adsorption→Primer Cooling→Finish Coating Roller Coating→Finish Curing→Correcting & Aligning→Cutting →Stocking

Color coated steel plate usually refers to the surface treatment of the substrate after the coating (roller coating) or adhesive organic film and baked products, can be further processed into the final product. The product has a beautiful color or pattern when it leaves the factory, so it is also called “color coated steel plate”. In our country color coated steel plate called more popular, and referred to as “color coated plate” or “color plate”.

The company's main color plate specifications: thickness of 0.12-1.5MM, width of 500-1250MM; the fastest speed of the unit: 150M/MIN; the types of coating layer include: polyester, silicone-modified polyester, polyurethane, vinylidene fluoride, high polyester, cyclic resins, acrylics, etc. The production line has the ability to meet the production of building panels, building materials, and the production of color-coated steel panels. The production line has the ability to meet the production of building boards, home appliance boards and other medium and commercial grade products. The line adopts two coating and two drying production process, with complete work procedure, and the drying oven adopts electric heating direct hot air circulation system.

Application Fields

Box containers

All kinds of vending machines, display cabinets, cans, compressed containers, storage rooms, etc.

Furniture and office equipment

Home appliance panels, furniture, automotive industry, security doors, shutters, etc.

Transportation industry

Automobile and train interiors, partitions, containers, barriers, ship partitions, air purifiers, various types of panels for ships, oil purifiers, driver's seat front panels, etc.

Agricultural Appliances

Desiccants and other agricultural equipment, greenhouses, silos, shell silos, warehouses, etc.

Architectural and Structural Engineering

The main body of a large-scale project's factory indoor, outdoor walls, roofs, corrugated use. Sandwich panel insulation for construction, drainage systems, ventilation systems, and other construction uses.

Underground construction, parking sheds, telephones, guest rooms, waiting rooms, and home decorative uses.

Electrical and Lighting Equipment

Refrigerators, washing machines, switchgear cabinets, instrument cabinets, air conditioners, microwave ovens, toasters, freezers, fluorescent light covers, switchboard boxes, motor boxes, photocopiers, etc.

Color coated sheet production line #2

The color coated sheet production line #2 was built in 2012 and began production in February 2013. With a faster production rate of 165 meters per minute and an annual output capacity of 250,000 tons, this line caters to a similar thickness range of 0.12mm to 0.6mm and widths of 700mm to 1250mm. It primarily manufactures standard building sheets utilizing novel processes and eco-friendly, non-toxic, odorless coatings. The products exhibit excellent corrosion resistance, weather resistance, vibrant colors, and long-lasting original hues without fading or peeling.

Category:

Color coated sheet production line #2

Keywords:

Color coated sheet