Galvanized sheet

Furthermore, the galvanized sheet production line #1 of the company, also built in 2009 and began production in May 2010, is designed to operate at 180 meters per minute with an annual production capability of 300,000 tons.

Description

Galvanized sheet production line #1

Furthermore, the galvanized sheet production line #1 of the company, also built in 2009 and began production in May 2010, is designed to operate at 180 meters per minute with an annual production capability of 300,000 tons. Focusing on standard galvanized sheets in thicknesses from 0.10mm to 0.3mm and widths of 700mm to 1250mm, these sheets find extensive application in automotive industries, refrigerated vehicles, construction, natural ventilation and heating equipment, as well as furniture manufacturing sectors.

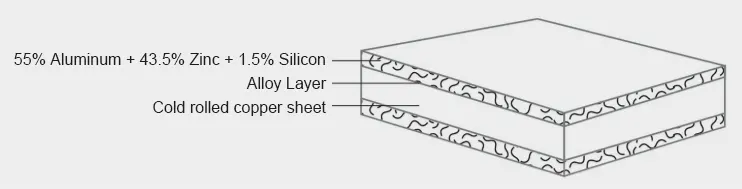

Galvanized sheet is a steel plate coating on the basis of zinc added aluminum (passivation protection), the general composition of 55% aluminum, 43.5% zinc, 1.5% silicon, with excellent resistance to atmospheric corrosion, corrosion resistance of galvanized sheet 2-5 times, but also has a high-temperature corrosion of the aluminum plate, the surface is smooth, the appearance of a good, but the formation of its plating and resistance to welding is slightly worse. In foreign countries, generally about 40% of the galvanized direct use, about 60% of the board is further - as a color coated substrate.

Use: Building roofs, walls, electrical cabinets, home appliances, automobiles, color coated substrates, etc.

Base Plate (Cold Rolled): It has advantages of high strength, easy processing, and economy, but it is easy to corrode.

Plated 55% aluminum zinc plate aluminum zinc coating: 55% aluminum + 43.5% zinc + 1.5% silicon and other trace elements.

Alloy Layer:Through the aluminum and iron to form a thin alloy layer, thereby inhibiting the growth of brittle zinc-iron alloy, increasing processability.

Plated 55% aluminum-zinc steel plate: plating by 55% aluminum, 43.4% zinc and 1.6% silicon composition, corrosion resistance is galvanized plate 2-6 times, characterized by high temperature corrosion resistance, smooth surface, good appearance, but the plating of the molding and weldability of a little worse.

Plated 5% aluminum-zinc steel plate: plating for 5% aluminum, 0.1% mixed rare earth elements, the rest for the zinc, corrosion resistance is galvanized plate 2-3 times, characterized by plating formation is very good, with good coating and welding performance, but the surface is not as bright as high alumina steel plate, fine, so few bare use.

Plating surface treatment method | Usage |

| Chromate passivation (C) | Surface treatment for high-strength steel plates after hot-dip plating to reduce white rust during transportation and storage |

| Chromate-free passivation (C5) | Surface treatments that require limiting the amount of hexavalent chromium, etc. in passivation solutions that are harmful to the environment and the human body |

| Fingerprint resistant (N) | Surface treatment after the passivation process, lubricates during processing, prevents fingerprints from staining during operation, and prevents premature blackening of the surface during use. |

| Chromate-free fingerprint resistant (N5) | Surface treatment after the passivation process, lubricates during processing, prevents fingerprint staining during operation, prevents premature blackening of the surface during use, and requires limiting the amount of hexavalent chromium in fingerprint-resistant films, which is harmful to the environment and the human body. |

| Oil coated (O) | Surface treatment added after the passivation process to further minimize corrosion during long-distance transportation and long-term storage |

Category:

Galvanized sheet production line #1

Keywords:

Galvanized sheet